The first Aerospace Academy is also known as the China Academy of Launch Vehicle Technology(CALT)

The project team led by the academician team

China Aerospace Science and Industry Corporation (CASIC) is China’s research and institute of aviation technology which integrates pre-research, development, production and support with complete supporting system and complete categories.

To be responsible for the organization, coordination and administration of scientific and technological research.

The quality and performance of products are first determined by the design scheme of R&D personnel.

In order to design the most suitable products for users, Newstar has established a research and development center, and equipped with a strong technical development team, which can customize the efficient, environmental protection and high quality products according to the different needs of customers.

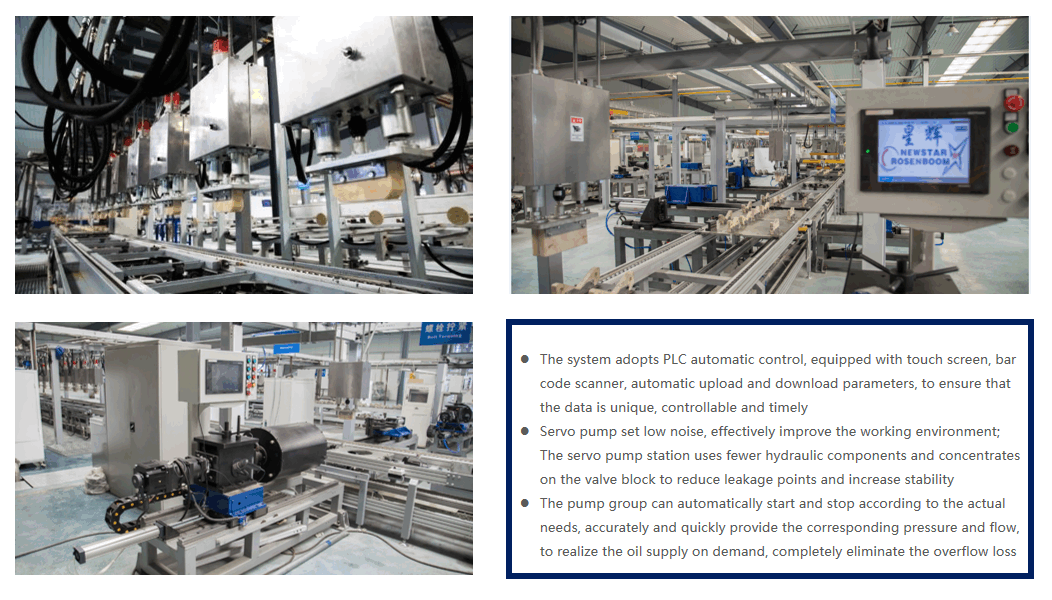

The system adopts PLC automatic control, equipped with touch screen, barcode scanner, automatic upload and download parameters, to ensure thatthe data is unique, controllable and timely

Servo pump set low noise, effectivelyimprove the working environment;The servo pump station uses fewer hydraulic components and concentrateson the valve block to reduce leakage points and increase stability

The pump group can automatically start and stop according to the actualneeds, accurately and quickly provide the corresponding pressure and flow.to realize the oil supply on demand, completely eliminate the overflow loss

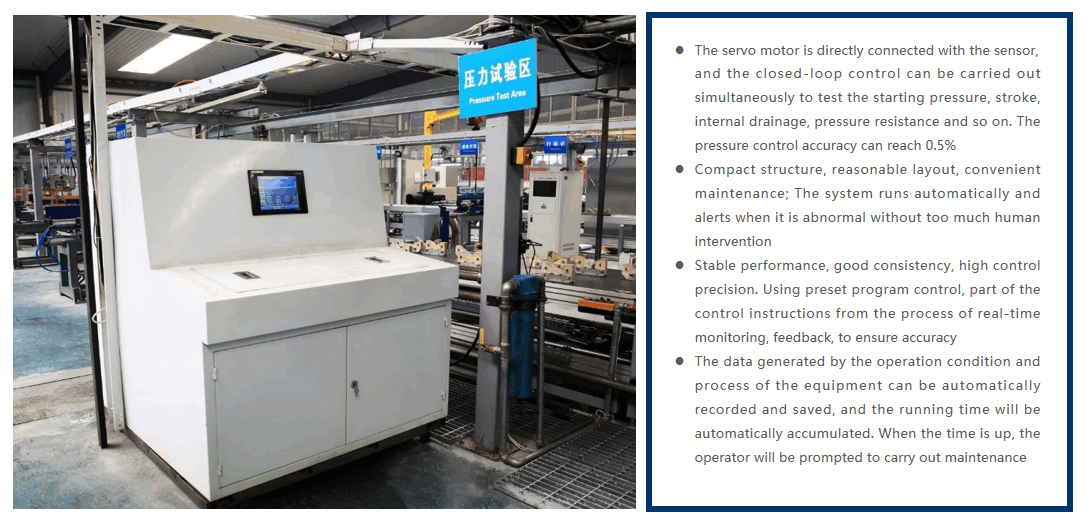

The servo motor is directly connected with the sensor,and the closed-loop control can be carried out simultaneously to test the starting pressure, stroke,internal drainage, pressure resistance and so on. Thepressure control accuracy can reach 0.5%

Compact structure, reasonable layout, convenientmaintenance; The system runs automatically andalerts when it is abnormal without too much human intervention

Stable performance, good consistency, high control precision. Using preset program control, part of the control instructions from the process of real-time monitoring, feedback, to ensure accuracy

The data generated by the operation condition and process of the equipment can be automatically recorded and saved, and the running time will be automatically accumulated, When the time is up, the operator will be prompted to carry out maintenance

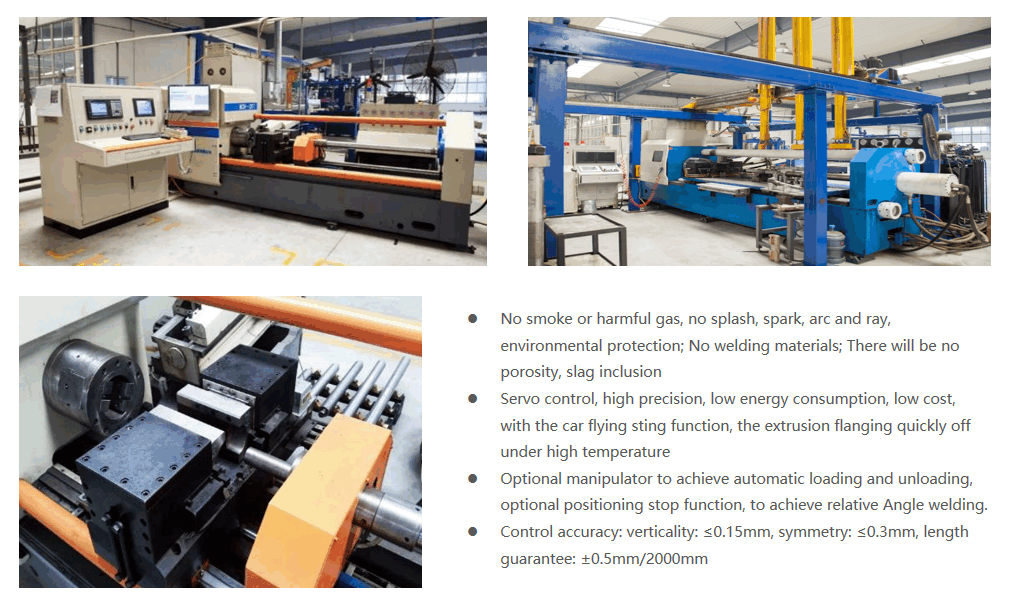

No smoke or harmful gas, no splash, spark, arc and ray.environmental protection; No welding materials; There will be no porosity, slag inclusion

Servo control, high precision, low energy consumption, low cost,with the car flying sting function, the extrusion flanging quickly off under high temperature

Optional manipulator to achieve automatic loading and unloading,optional positioning stop function, to achieve relative Angle welding.

Control accuracy: verticality: <=0.15mm, symmetry: <=0.3mm, length guarantee: +-0.5mm/2000mm